INSIGHT IR®

Continuous Thermal Intelligence

The next evolution of power distribution safety - designed to detect thermal issues long before they become failures. Always on. Always watching. Always protecting.

Explore Key Features Download BrochureThermal Failures Don’t Announce Themselves.

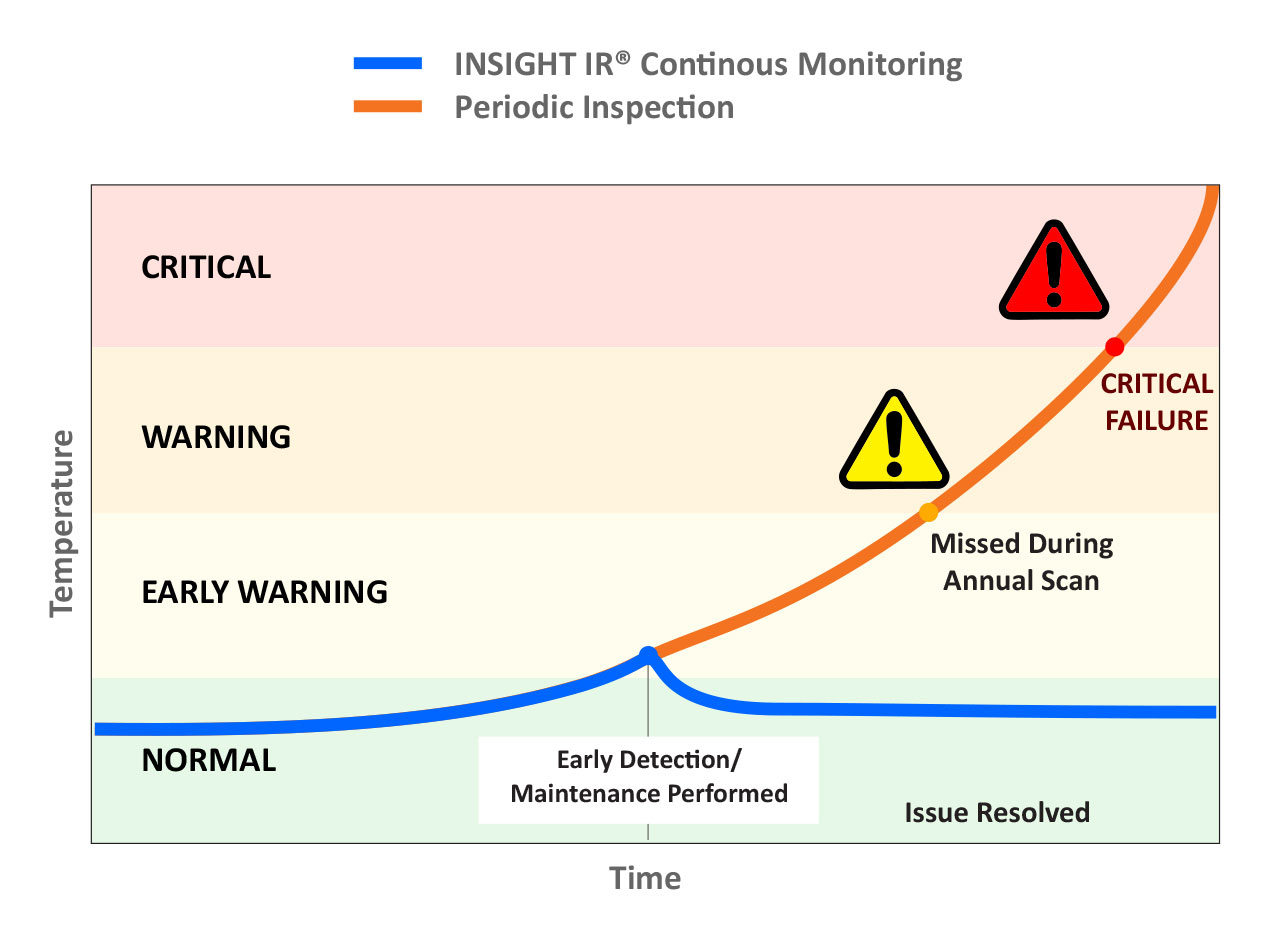

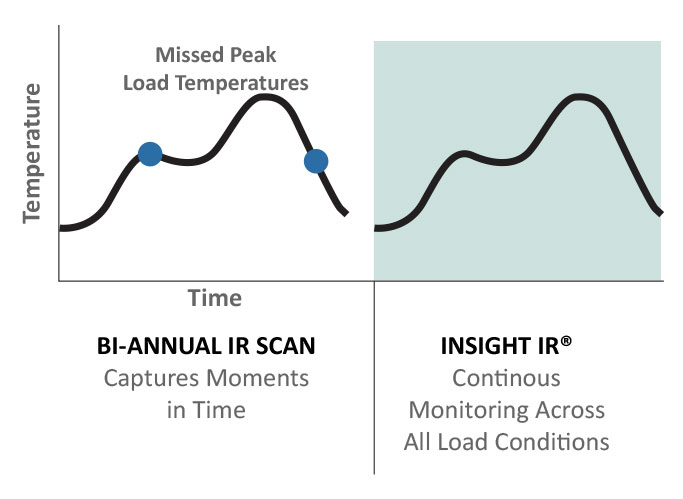

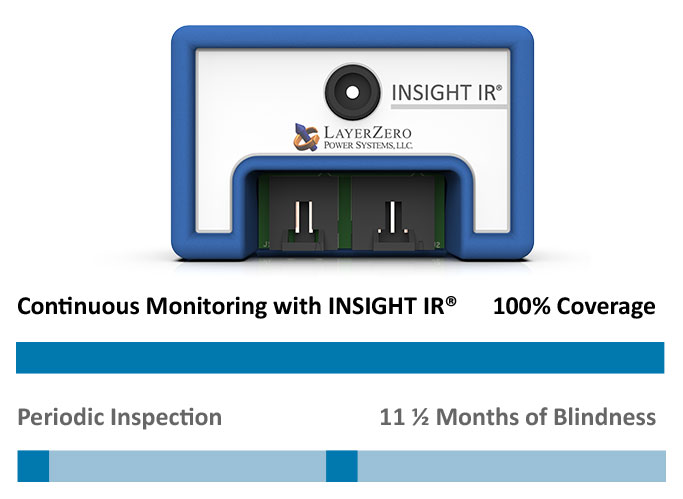

Most electrical failures begin as subtle, slow-growing thermal issues-loose hardware, degraded contacts, or uneven pressure that quietly add heat over time. Annual handheld IR scans catch only a single moment in that progression, leaving long stretches where critical conditions can go unseen.

INSIGHT IR® closes that gap. Fixed infrared cameras continuously watch the same connection points day after day, building a live thermal profile that surfaces abnormal trends well before they trigger alarms or outages.

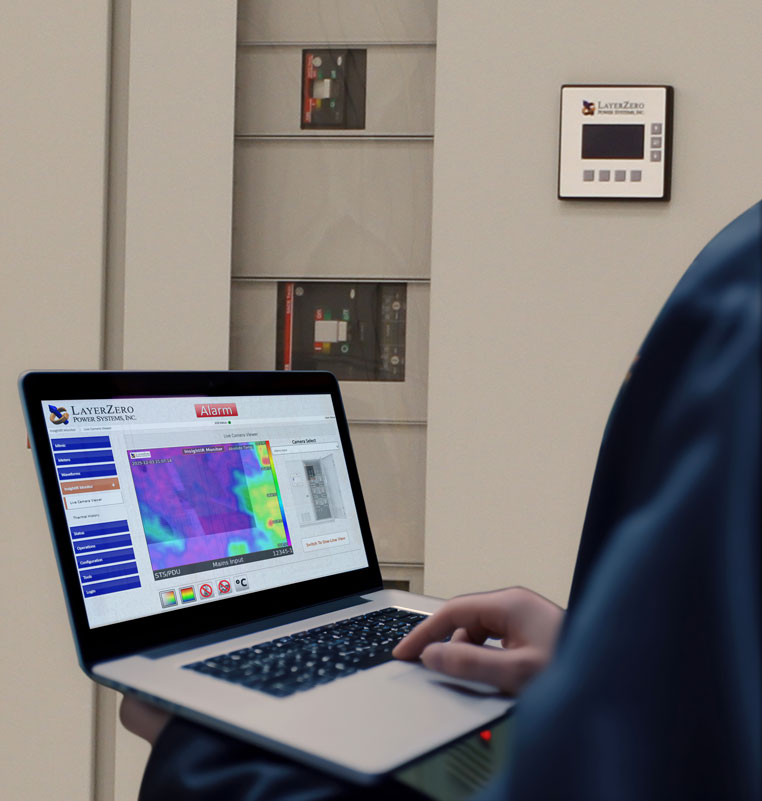

24×7 Monitoring for Peace of Mind.

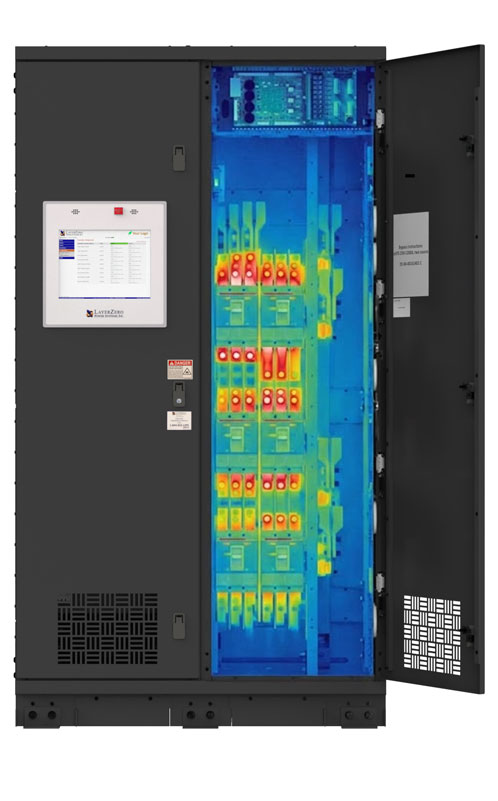

INSIGHT IR® continuously monitors internal power distribution components, capturing a steady stream of temperature data throughout the day, every day. Instead of fragments of information during test windows, you see how connections behave under real load conditions-light load, peak load, and everything in between.

The result is a stable thermal baseline for each monitored point, making even small deviations easier to spot and act on before they evolve into critical events.

- Continuous coverage of high-risk connection points

- Thousands of reference points collected over time

- Trend visibility between maintenance cycles

Annual Inspections See Two Days. INSIGHT IR® Sees the Other 363.

Thermal faults develop gradually. If you only look at them once or twice a year, most of that development happens off-camera. A scan taken during a light-load condition might show everything “normal” while the same connection runs hot at peak demand.

With INSIGHT IR®, monitoring doesn’t stop when the technician leaves. You gain continuous insight into the exact locations where failures typically begin-lug connections, bus interfaces, and other critical joints inside your power distribution equipment.

- Fewer blind spots from limited access windows

- Thermal behavior tracked across real operating conditions

- Earlier intervention when issues first begin to drift out of normal

Built-In Reliability. No Energized Doors Opened.

Traditional IR programs depend on opening energized equipment, coordinating specialized technicians, and scheduling around live loads. Every scan adds risk and recurring cost, while still leaving uncertainty between visits.

INSIGHT IR® is built into the equipment from day one, providing continuous thermal intelligence with almost no ongoing burden for operations teams.

- Reduced need to open energized cabinets for routine thermal inspections

- Less reliance on external IR service providers and scheduled site visits

- More predictable, data-driven maintenance planning

Designed for Mission-Critical Power Distribution.

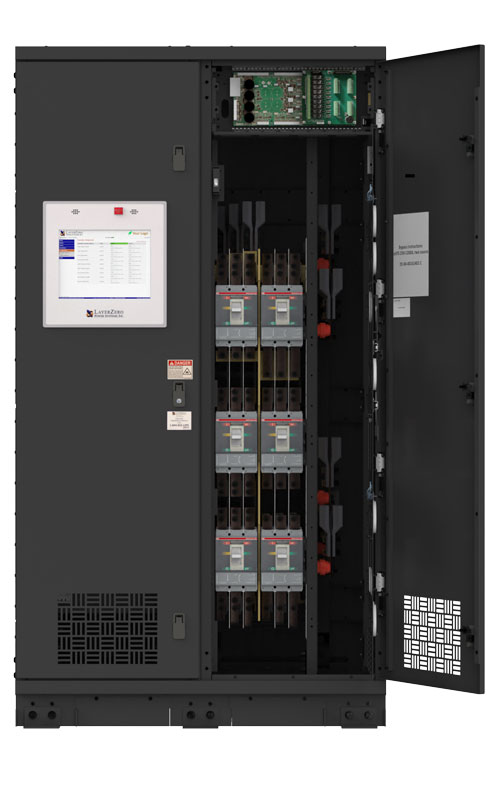

INSIGHT IR® is engineered for environments where uptime is non-negotiable and thermal events have real business impact. Embedded directly into LayerZero Power Systems products, it gives operators a clearer view of the most important connections in the room.

- Data centers and AI / GPU cluster power infrastructure

- Financial trading and transaction processing environments

- Semiconductor Manufacturing

- Industrial and process facilities with high continuity requirements

A Smarter Approach to Power Distribution Reliability.

INSIGHT IR® improves thermal monitoring from an occasional check to a continuous source of actionable intelligence. By embedding thermal awareness directly into LayerZero Power Systems equipment, it improves safety, reduces operational risk, and supports long-term reliability for mission-critical loads.

- Continuous thermal monitoring of critical connections

- Early warning before temperature issues become service events

- Improved safety, reliability, and operational efficiency over traditional IR programs